User study

User study

Aug 7,2017

S-Tooling is a die industry player capable of a stable and quick supply of accurate and weight-saving products through a mass-production methodology implemented by an unconventional team concept and production process. The company has served fastidious automobile manufacturers around the world for more than 25 years. It aims to become a leading automobile die supplier capable of merging die manufacturing technologies and concepts in Japan with those of Western countries.

The company has systematically implemented training for engineers in order to enhance their expertise enough to meet the demands for quick turnaround of high-quality products.

Furthermore, S-Tooling, keen on stabilizing product quality, has made studious efforts to brush up on designing technologies on the basis of constant improvements and acceptance of new concepts and technologies in the field.

CADmeister, enabler of anticipation of deformation amounts, was selected

There has been an incessant increase in the use of aluminum alloys and high tensile steels in response to automobile chassis losing weight in recent years. The company decided to use CADmeister Press capable of effectively anticipating deformations caused by these materials such as springback and torsional behaviors.

They had to experience suffering from complicated mechanics in order to compensate manually such deformations before turning to CADmeister. CADmeister, enabling them to verify simulated deformation statuses, has served them in eventually reducing deformation workload.

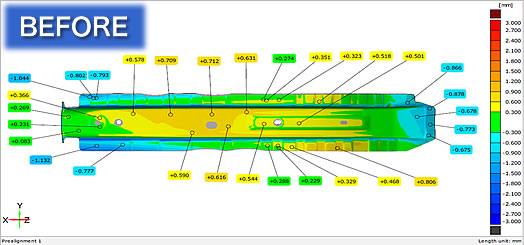

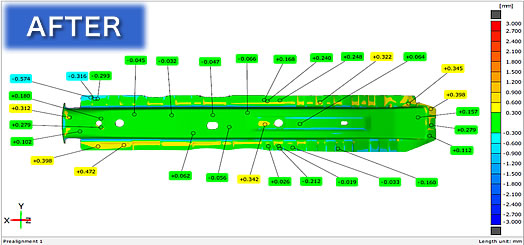

Example of Deformation about ‘Reinforcement-fr-side-member-rr’ part (part to reinforce front side)

It is a result of measuring metal sheets that they shaped through machine pressing for trial before introducing CADmeister. Their difficult attempts of transforming metal sheets based on complicated mechanical considerations only resulted in significant errors, and thus needed repetition.

This shows a measurement result of metal sheets after introducing CADmeister. They were shaped on a trial basis by CADmeister’s capability of anticipating mechanical deformation amounts. CADmeister enables a quick transformation within an allowable error range, and thus served in reducing workload.

1. 590 MPa or higher tensile steel sheets and aluminum sheets have been popularized as press die materials, in response to global demands for less weight car chassis. They expect CADmeister more capable of referring to detailed material characteristics and creating further reliable transformation.

2. There are also expectations for STL transformation capabilities against a backdrop where reverse engineering through the use of coordinate measuring machine CMM is further focused. They expect CADmeister to be enhanced with STL-use capabilities to process deformation.

The most critical part of handing over a family business is to give experience and a suitable business platform over to the next generation. Our automobile die industry requires various types of experience and careful work processes.

We need to improve our service quality for customers who continuously complicate their requests. On the other hand, we need to have employees become proud of working in this industry where mobility of human resources is witnessed.

We think that we will enable a win-win relationship of our customers and employees only through the use of new tools. New tools will enable us to innovate manufacturing processes capable of responding to changes in the times. They will also give us opportunities of creating a system of developing skillful and self-proud workforce through tool training. CADmeister is a tool partnering with us in accumulating experiences.

We comfortably work, learn new knowledge, value experiences, and create value at S-Tooling. This corporate culture of making incessant studious efforts for the maximum benefit of customers will help our continued corporate image. (General Manager Mendy Chiu)

In the challenging business environment where we are faced with market demands for shorter durations for developing molds/dies of higher quality, we will make continuous efforts to cast away our previous manufacturing methodology and process, and totally improving the manufacturing process, equipment and safety management apparatus. We will re-create S-Tooling into a new comfortable entity capable of efficiently creating higher quality products. S-Tooling will challenge its limits and continue to venture advancement in the automobile die industry.

(Department Manager Tim Peng)

<Interviewed in July 2016>

*** The company names and product names described herein are trademarks or registered trademarks of their respective owners.

*** The names of local autonomous bodies, companies and individuals were given in the interview.