Function(CAM)

Function(CAM)

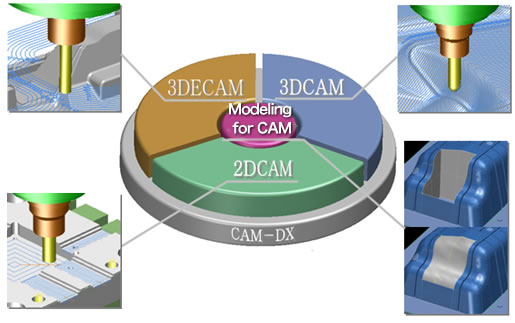

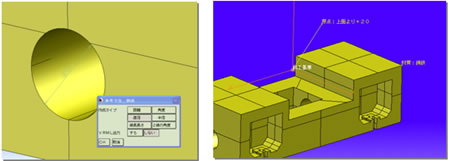

CAM-DX is a CAD/CAM system that consists of a CAM engine based on CADmeister/CAM. The CAM engine has been manufactured by C&G SYSTEMS INC. a recognized company for machining resin molds. CADmeister/CAM is a proven system for press die machining. Thus, CAM-DX is a combination of high-speed and high-quality machining methods and conventional proven methods. It can respond to a wide variety of users' needs.

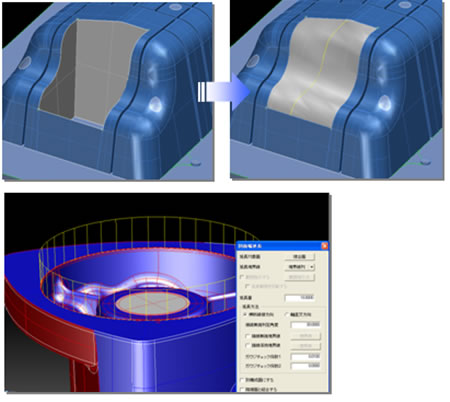

CAM-DX supports the machining modes: 2DCAM (hybrid 2D CAM), 3DCAM (hybrid 3D CAM) and 3DECAM (GP-CAM). Thus, it can create paths that fit various types of machining such as holing in an assimilated environment of 2D and 3D machining. Furthermore, the modelling capability of streamlining CAM operations as well as the capabilities of editing and analyzing surfaces improve the machining efficiency and the quality of paths.

3DECAM enables high-speed and high-quality machining due to CAM-TOOL engine (GP-CAM) supported by C&G SYSTEMS INC. (which has an alliance with UEL Corporation.)

The "Contour_Rough" command

The "Contour_Rough" command The "Contour_Rough_Primary Machining" command

The "Contour_Rough_Primary Machining" command The "Contour_Finish" command

The "Contour_Finish" command The "Concave_Uncut Portion_Contour" command

The "Concave_Uncut Portion_Contour" command The "Concave_Uncut Portion" command

The "Concave_Uncut Portion" commandCorrection of CAM Figures

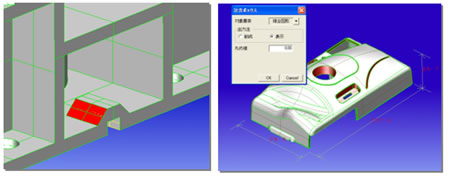

This category of functions to improve the quality of paths include the functions of filling in holes and creating support surfaces for machining. They are: the Form_FillingBase" command, the "Form_FillingNotch" command, the "FillingLargeHole" command, the "CollecVertexDeletion" command, the "TopOp_AddBdCrv" command, the "One-time correction" command, the "AlignEndPnt" command, the "SrfEdgeExtension_Separate" command, the "Create_FuzzyOffsetSurface" command, the "SectionalDieBandSurface" command, the "RemoveDupLines" command, the "Curves unification" command, and the "CompulsoryUniteCrv" command.

CAM Analysis

CAM Analysis helps the confirmation of shapes and the calculations of paths in a phase of examining manufacturing processes. They are enabled by the "Check_DuplicateSurfaces" command, the "SimpleUndercutCheck" command, the "ContainerBox" command, the "Disp_HeightDim" command, the "FigureRetrieval" command, the "GeomCheck" command, the "ConvertToFreeSrf" command, the "ConvertToAnalyticSrf" command, and the "Reduce_BaseSrf" command.

CAM Dimensions and Annotations

The functions of 'CAM Dimensions and Annotations' display dimensions of shapes and 3D annotation data and also output them in machining instruction manuals and so on. They are performed by the commands: the "RefDim_Create" command, the "RefDim_DispON" command, the "RefDim_DispOFF" command, the "3DAnnotation_Create" command, the "3DAnnotation_Change" command, the "3DAnnotation_Delete", the "3DAnnotation_Move" command, the "3DAnnotation_ChgProperty" command, the "3DAnnotation_DispON" command, and the "3DAnnotation_DispOFF" command.

If you have any inquiries about our product or would like to request a visit to your place for explanation or demonstration, please use the inquiry form.

![]() Inquiry form

Inquiry form