Function(CAM)

Function(CAM)

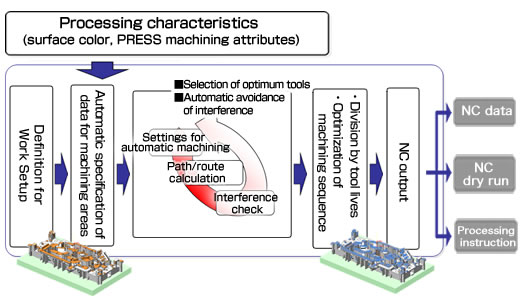

This system automatically processes a subject area on the basis of the characteristics data of press machining. It also automatically creates paths for the primary machining of a Structure, ferrous die of receiving a press die 'insert'. The paths have been standardized through the use of knowledge database.

Furthermore, the capability of optimizing the processing sequence enables users to rearrange the NC (numerical control) output sequence pursuant to specified rules (about processing sequences and replacement of tools). Users can also segmentalize the NC output order through the use of tool life.

This system automatically processes specified areas based on the characteristics data of processing. It also automatically creates reliable and highly efficient machining paths in order to standardize, automate and optimize the machining of a Structure.

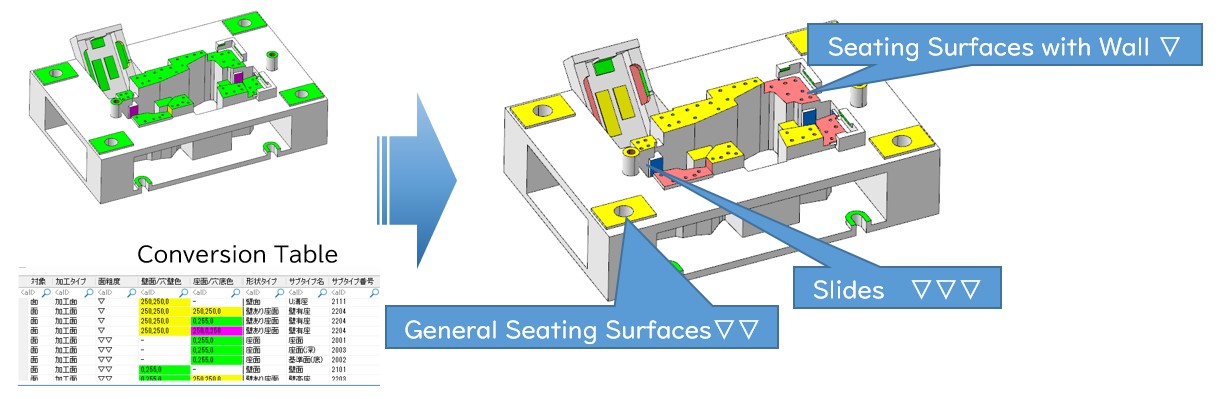

The “ConvertMachiningFeature” command can automatically identify surfaces where Shading Colors (RGB values) are assigned in accordance with the Conversion Table, and collectively add cutting attributes necessary for enabling Path Computation.

The “ConvertMachiningFeature” command can automatically add cutting attributes suitable for cutting methods in coordination with Path Computation in the subsequent processes.

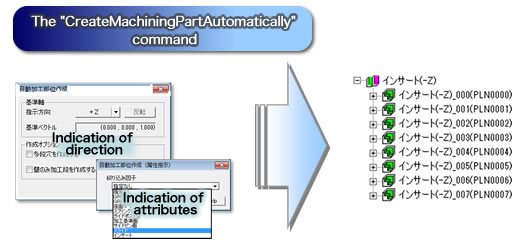

The system enables users to set as 'Machining Part' the data such as: areas subject to processing, decisive factors for phase schedules, and margins.

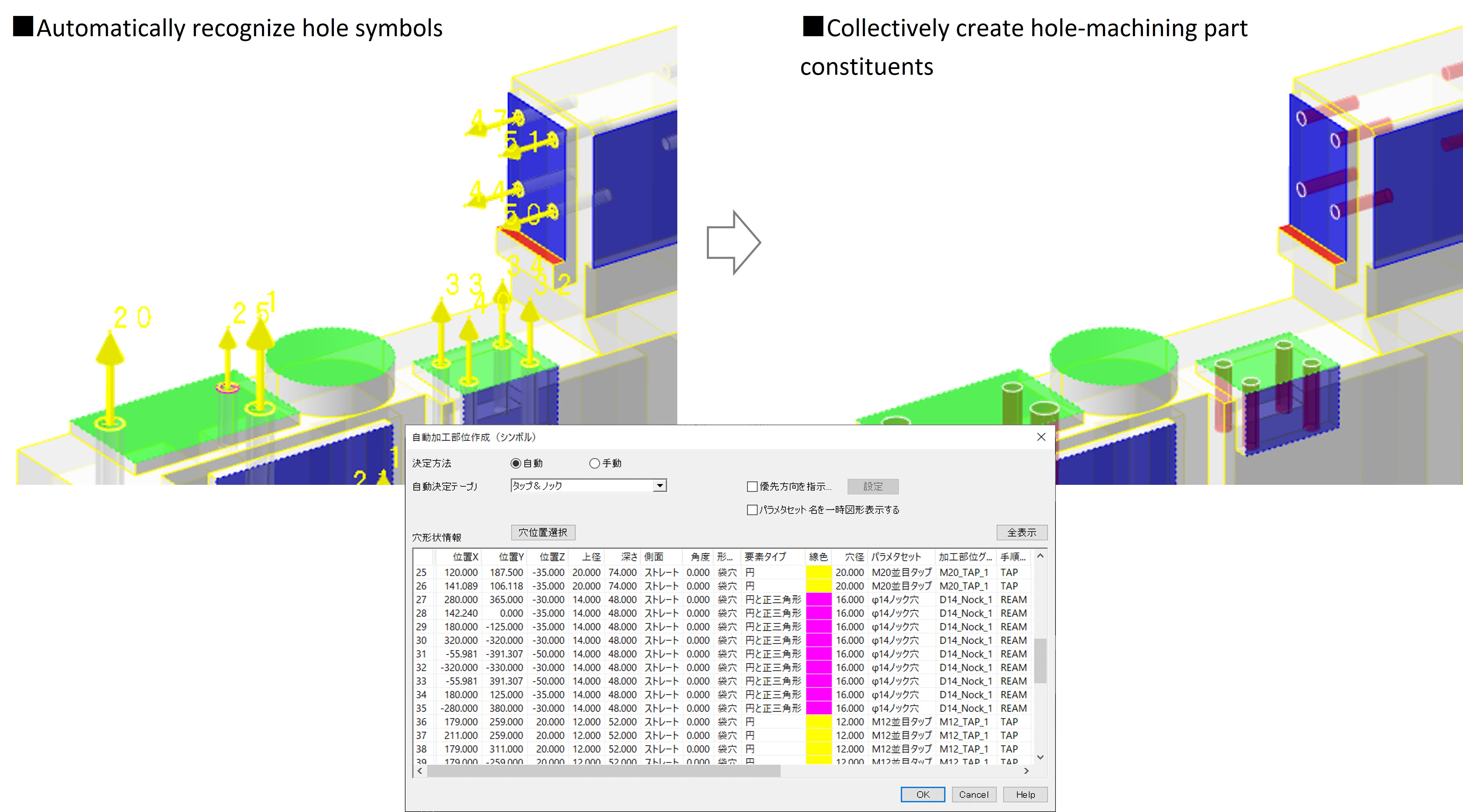

This command creates collectively a variety of hole machining part constituents regardless of directions, through the use of symbols that indicates hole positions and colors.

The command automatically decides upon a 'parameter table of hole-machining part consituents' through the use of 'types, colors and diameters of symbols'. Thus, the command enables a reduction of workload about creating hole-machining data.

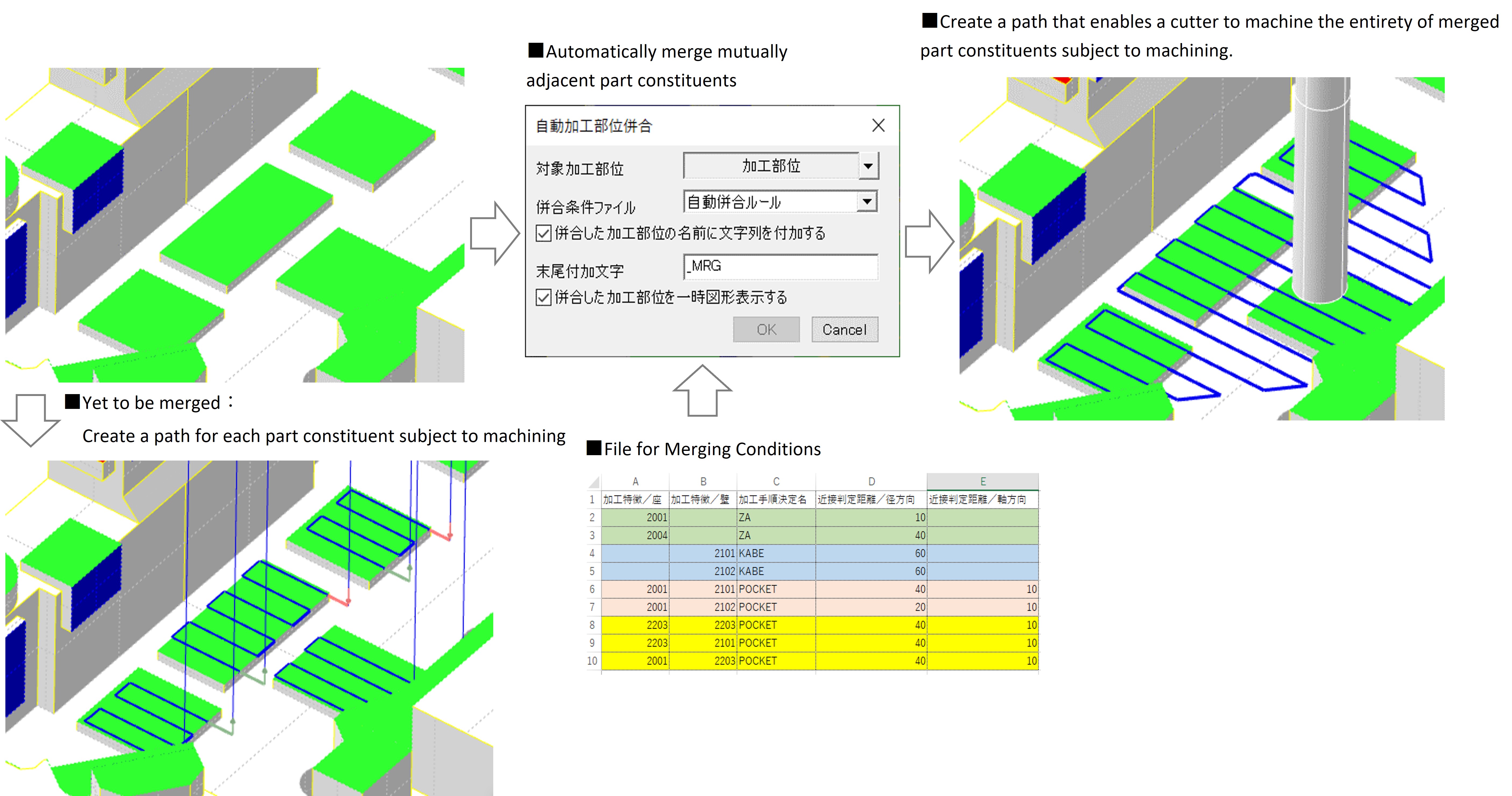

The command creates a path that reduces a cutter movement from a part constituent to another by automatically merging machining part constituents that are adjacent each other and are of the same machining attributes.

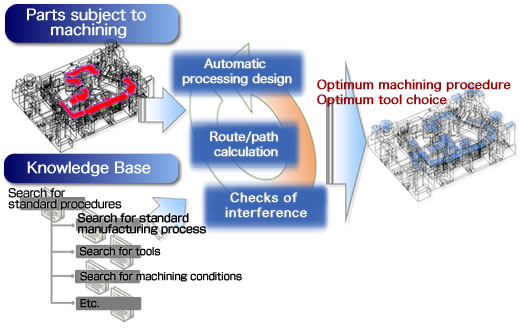

Optimum processing procedures, tools, and processing conditions can be automatically decided based on the data of Knowledge Database.

Paths/routes that do not cause interferences can be created on the basis of the understanding of the surrounding shapes.

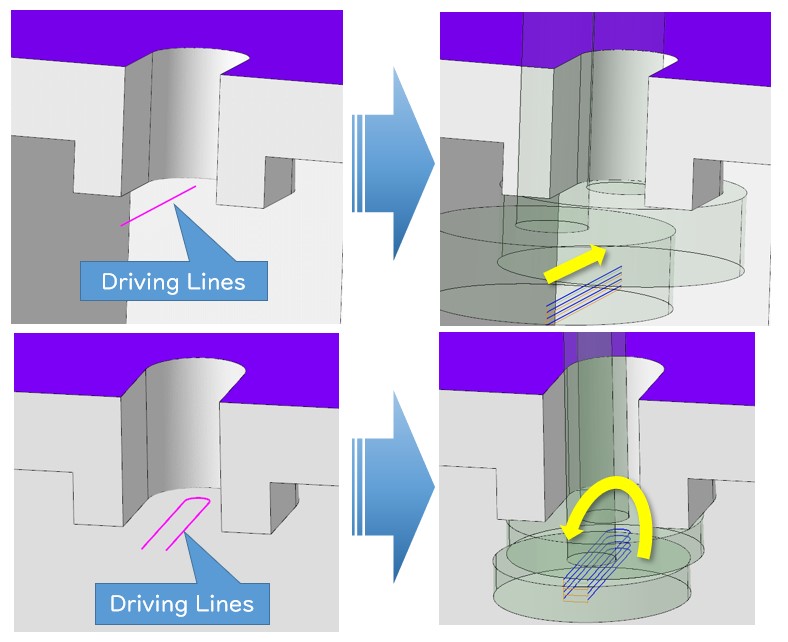

The “ConvertMachiningFeature” command enables the System operators to create easily paths for a T-Slot cutting tool to cut a U-Slot seating surface.

The “ConvertMachiningFeature” command sets Driving Lines that constitute basic forms of path, and creates paths for linear motions and U-letter motions based upon the Driving Lines.

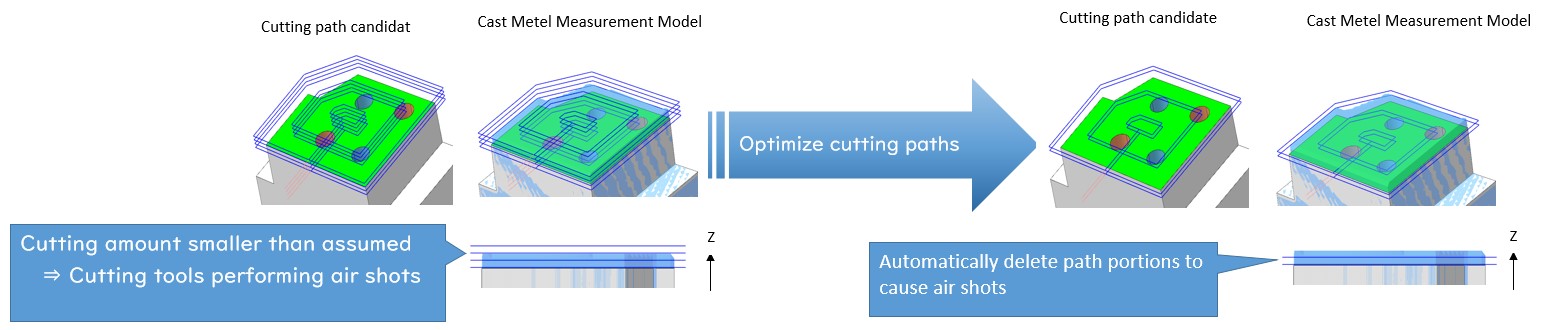

The “CAM-STRUCTURE” command checks path candidates that the System operators created in order to cut a cast metal by comparing with the cast metal measurement data by a 3D measuring device.

The command automatically deletes dead time portions of the path candidates where cutting tools perform air shots.

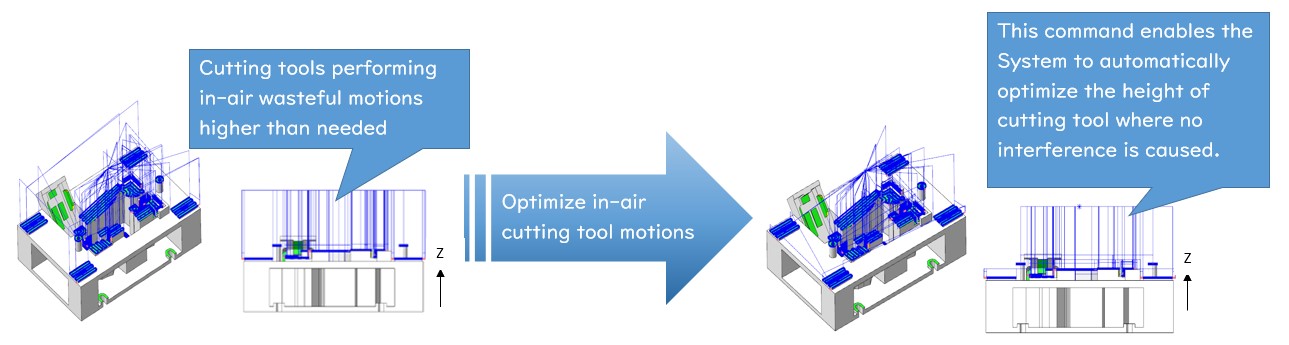

The “OptimizeIn-airCuttingToolMotions” command automatically optimizes in-air motions performed by a cutting tool through vertical adjustments and denies interference.

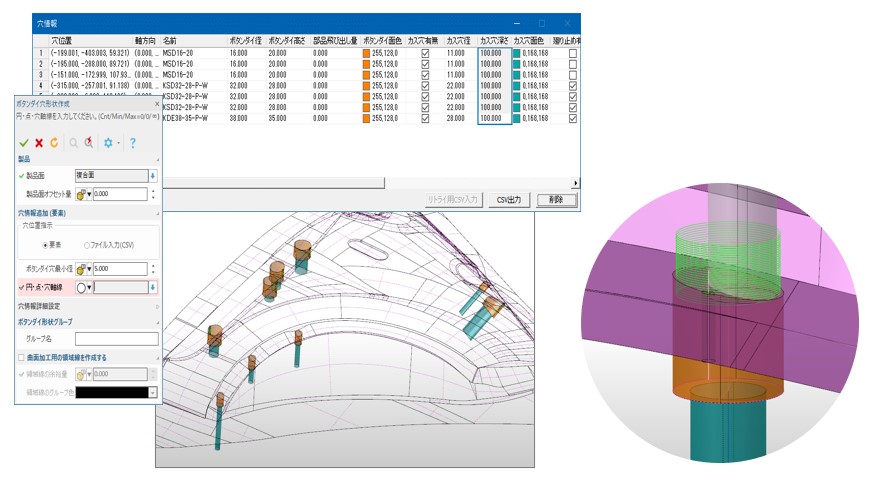

The “CreateButtonDieHoleShapes” command collectively creates Button Die hole shapes that match the Button Die parts to be inserted.

The “CreateButtonDieHoleShapes” command creates Button Die hole models based upon considerations about thickness of sheet metal and an entire die structure. Thus, the System operators are saved from troubles about adjusting depths for cutting Button Die holes in light of a reference position.

The System operators can reduce workloads for creating data needed for cutting Button Die holes in a press-forming die by executing this command in coordination with the "CAM-STRUCTURE" command.

If you have any inquiries about our product or would like to request a visit to your place for explanation or demonstration, please use the inquiry form.

![]() Inquiry form

Inquiry form