CAM-ATTRIBUTE (CAM for coordinating attribute data)

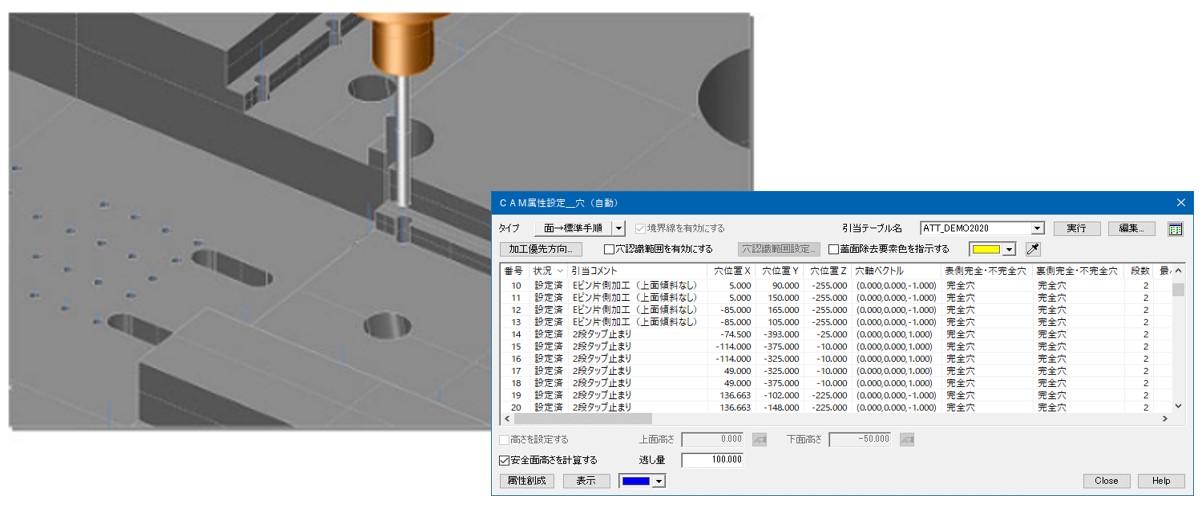

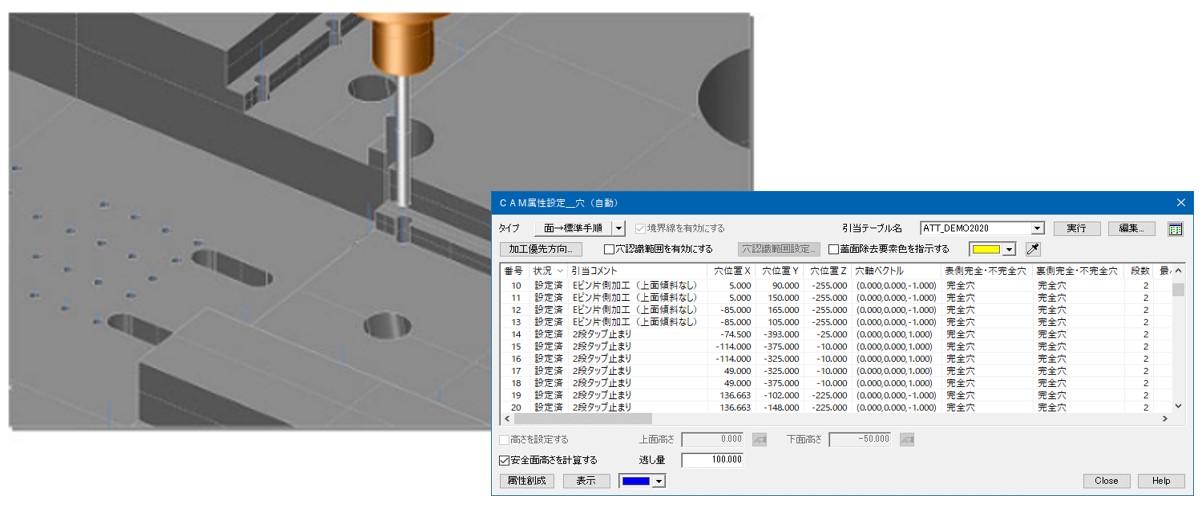

The “CAM-ATTRIBUTE” command automatically creates standardized hole machining data through the use of hole machining attributes as geometric characteristics of figures or those assigned in the designing phase.

The command creates hole machining data on the basis of various types of data, 2D or 3D, including those generated in the phases of upstream design such as solid models and drawings as well as hole positions (in CSV files).

The command efficiently creates data for machining holes without causing cutting tools to interfere, on the basis of considerations about machining procedures of Intersecting Holes, and inclination angles at hole entrance as well as interference caused by cutting tools.

Furthermore, the command automatically creates standardized hole machining data on the basis of Pocket Machining Attributes assigned to solid models.

Features

Assignment of Machining Attributes

- Automatic attribute settings for 2D/3D geometrical shapes

- Assignment of machining attributes to the data of hole positions and Pocket shapes that have been imported from machining information (CSV) files

- Capability of importing machining attributes that have been assigned to CADmeister MOLD (support for mold designers)

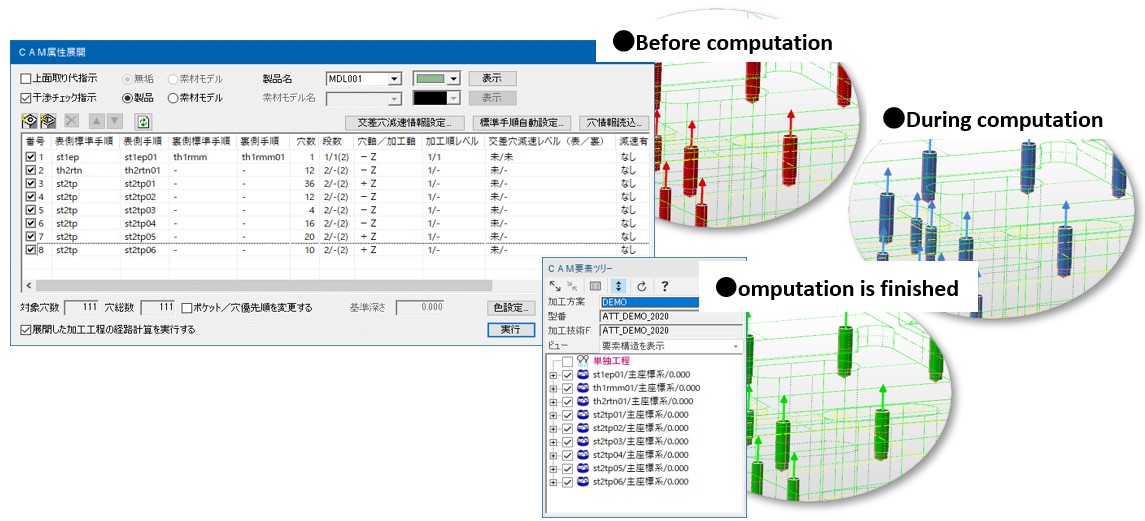

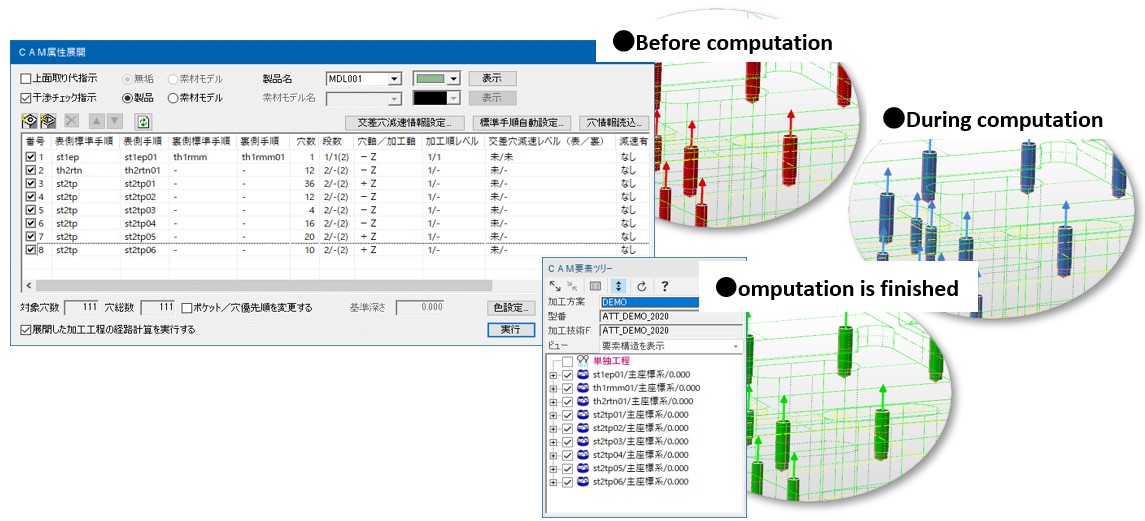

From the Phase of Creating Machining Processes to the Phase of Path Computation

- The System operators can implement the phases from creating machining processes, path computation, and intereference check by a simple click on the command window of the “CAM-ATTRIBUTE” command.

- Furthermore, the System operators need only this command window of the “CAM-ATTRIBUTE” command in order to operate the System through the phases from that of managing attribute data to that of editing attribute data and even confirm

with hole colors of models visually situations of path computation.

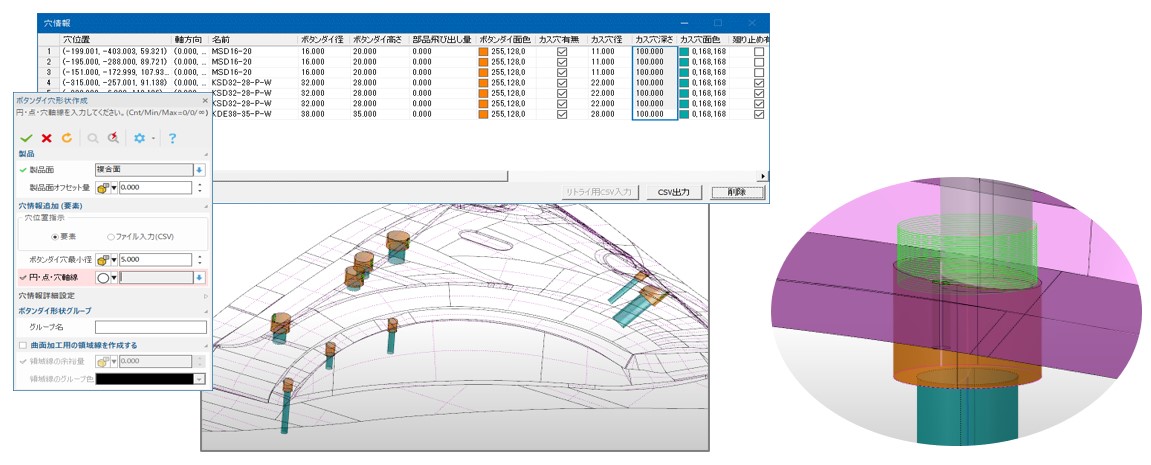

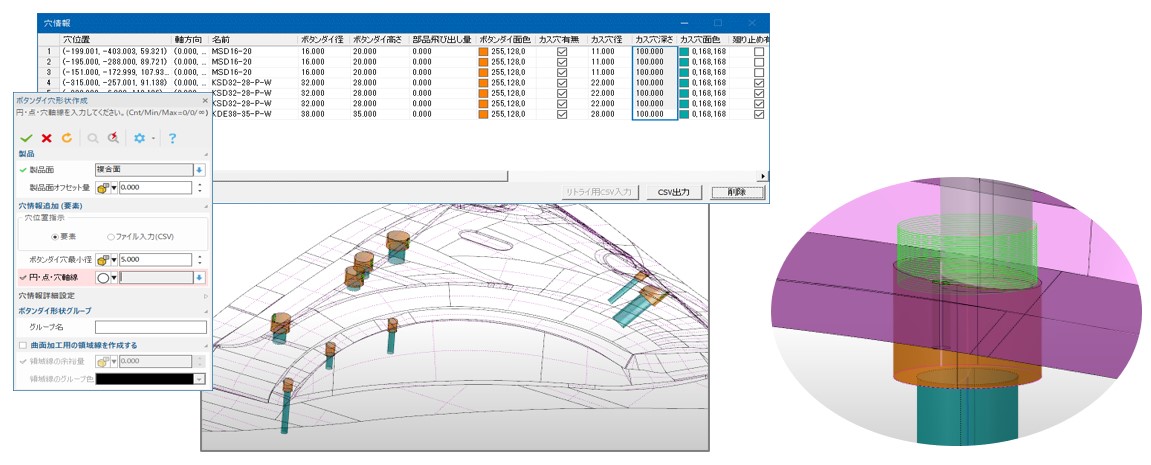

Create Button Die Hole Shapes

- The “CreateButtonDieHoleShapes” command collectively creates Button Die hole shapes that match the Button Die parts to be inserted.

- The “CreateButtonDieHoleShapes” command creates Button Die hole models based upon considerations about thickness of sheet metal and an entire die structure.

Thus, the System operators are saved from troubles about adjusting depths for cutting Button Die holes in light of a reference position.

- The System operators can reduce workloads for creating data needed for cutting Button Die holes in a press-formiing die by executing this command in coordination with the “CAM-ATTRIBUTE” command.

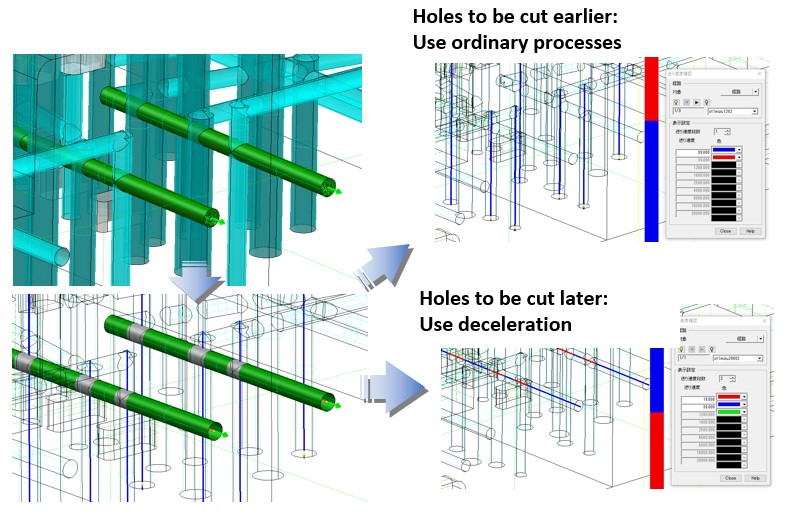

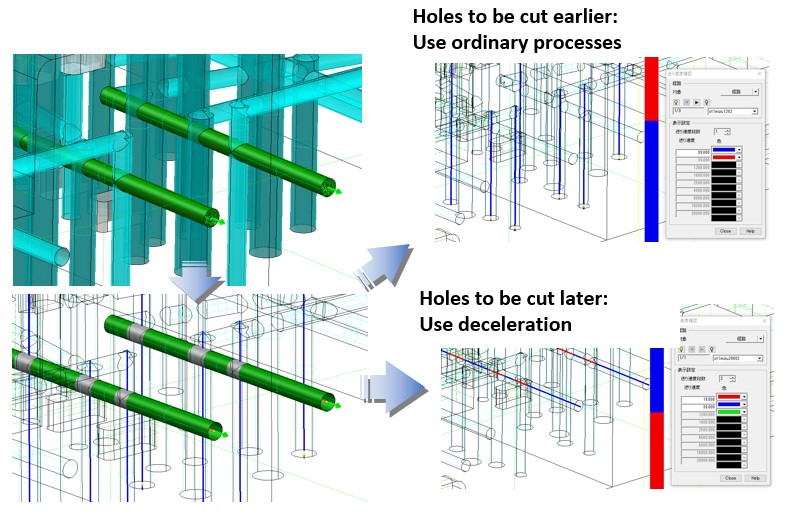

Cutting Speed Control for Intersecting Holes

- The System can control feed rates of cutting tools in accordance with the sequence for cutting Intersecting Holes (holes made by water tubes intersecting each other). The “CAM-ATTRIBUTE” command creates data for controlling the feed rates.

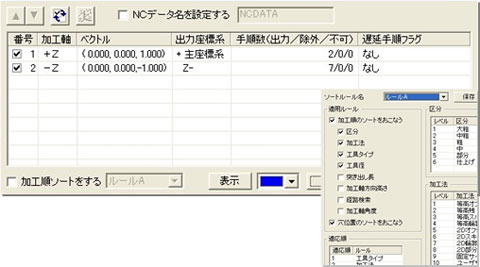

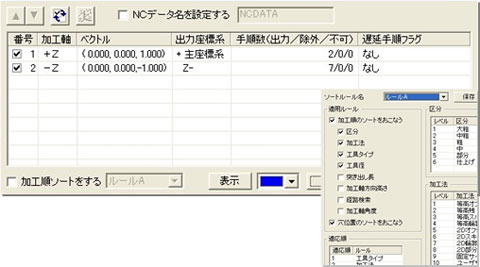

Command of Collective NC Output for Hole Machining

- Machining phases can be automatically grouped by direction without considering a machining axis.

- Users' own machining sequences can be optimized pursuant to situation-specific sorting rules.

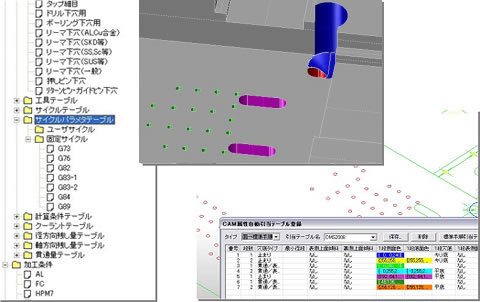

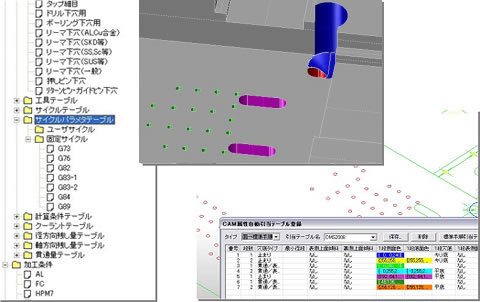

Setting of Various Types of Tables for Hole Machining

- Tables that describe conditions for creating hole-machining data can be created by a special GUI tool.

- Machining expertize can be standardized by combining individual Tables.

Inquiries

If you have any inquiries about our product or would like to request a visit to your place for explanation or demonstration, please use the inquiry form.

Inquiry form

Inquiry form

![]() Inquiry form

Inquiry form