Function(CAM)

Function(CAM)

CAMEDIT enables users to edit and make paths that are easily operable and highly efficient for machining. Through the use of CAMEDIT, users can edit entire paths, base paths and path points and also sort the sequence of paths. Furthermore, CAMEDIT enables users to calculate the length beneath the head of blade holder and thus divide paths into machinable sections accordingly. It helps users by creating paths capable of machining the areas that have been left uncut.

It is possible to utilize users' own expertise of editing paths through the use of a wide variety of capabilities of CAMEDIT, and thus improve machining efficiency.

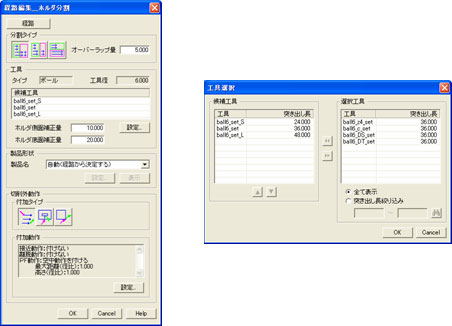

Paths can be divided into sections that can be machined by the unit of the length beneath the head of a tool holder with blade, provided that the paths have been calculated. Note that the length beneath the tool head varies depending on the combination of holder and blade.

Paths can be edited in order to machine only any uncut areas, by specifying the area and choosing a shape and paths of the previous machining.

If you have any inquiries about our product or would like to request a visit to your place for explanation or demonstration, please use the inquiry form.

![]() Inquiry form

Inquiry form