Function(CAM)

Function(CAM)

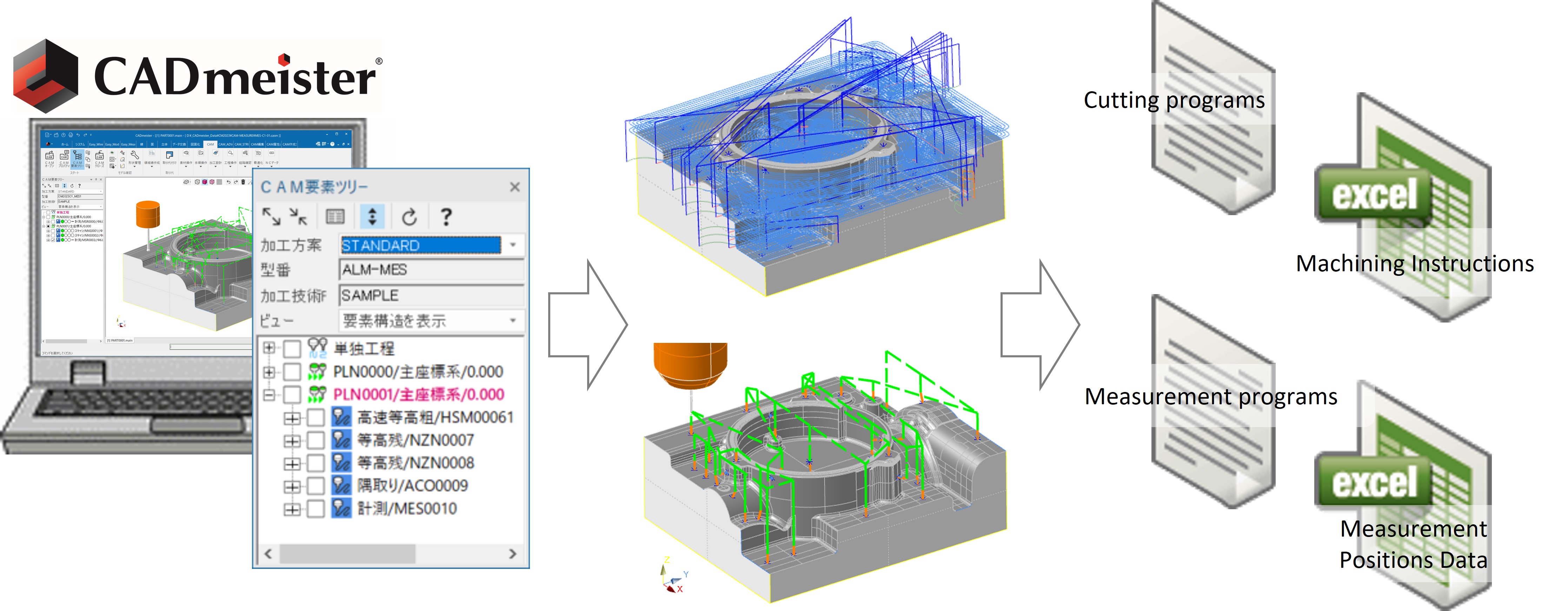

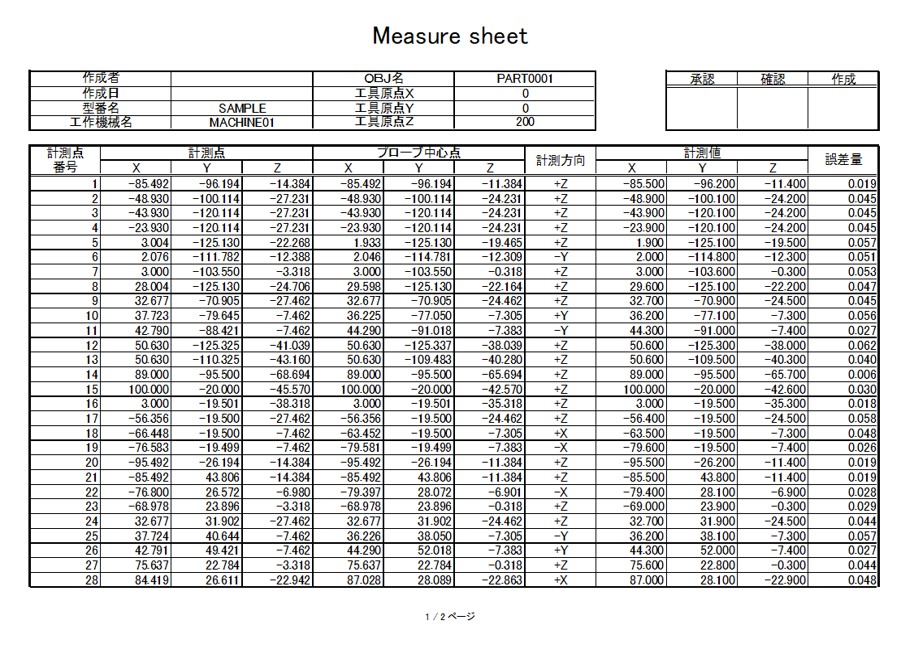

CAM-MEASURE creates measurement programs to verify machining preciseness on a machining device. CAM-MEASURE combines measurement programs with cutting programs into a set of processes, and creates measurement programs and measurement positions data through the oridnary CAM operations. CAM-MEASURE supports ensuring a precise cutting process without requiring machined work pieces to be removed from a machining table.

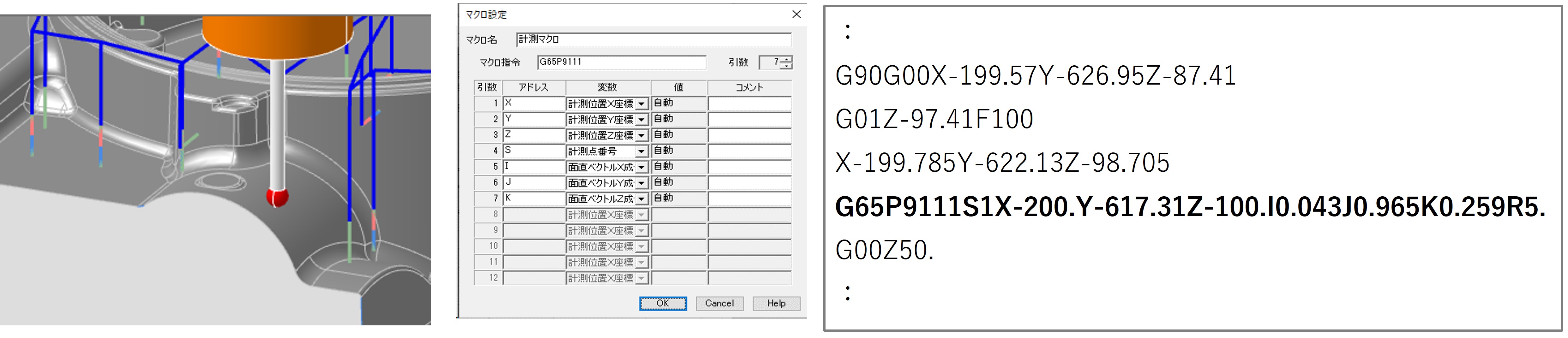

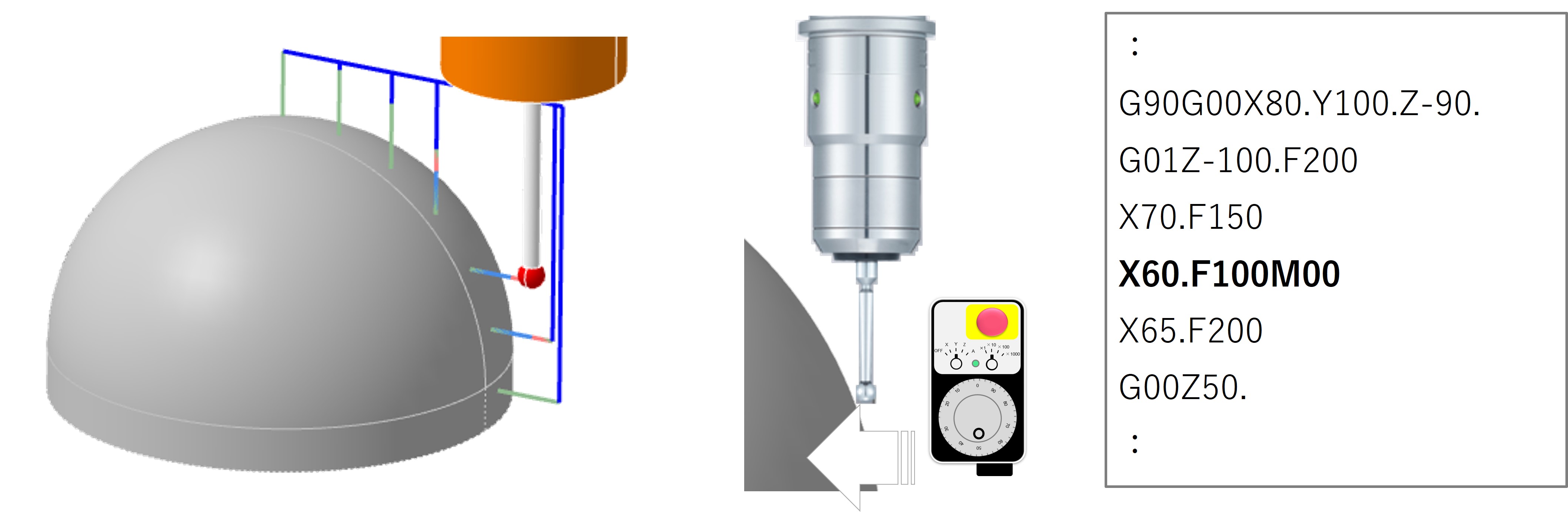

CAM-MEASURE supports automatic measurement enabled by using measurement macros and manual measurement enabled by Handle operations.

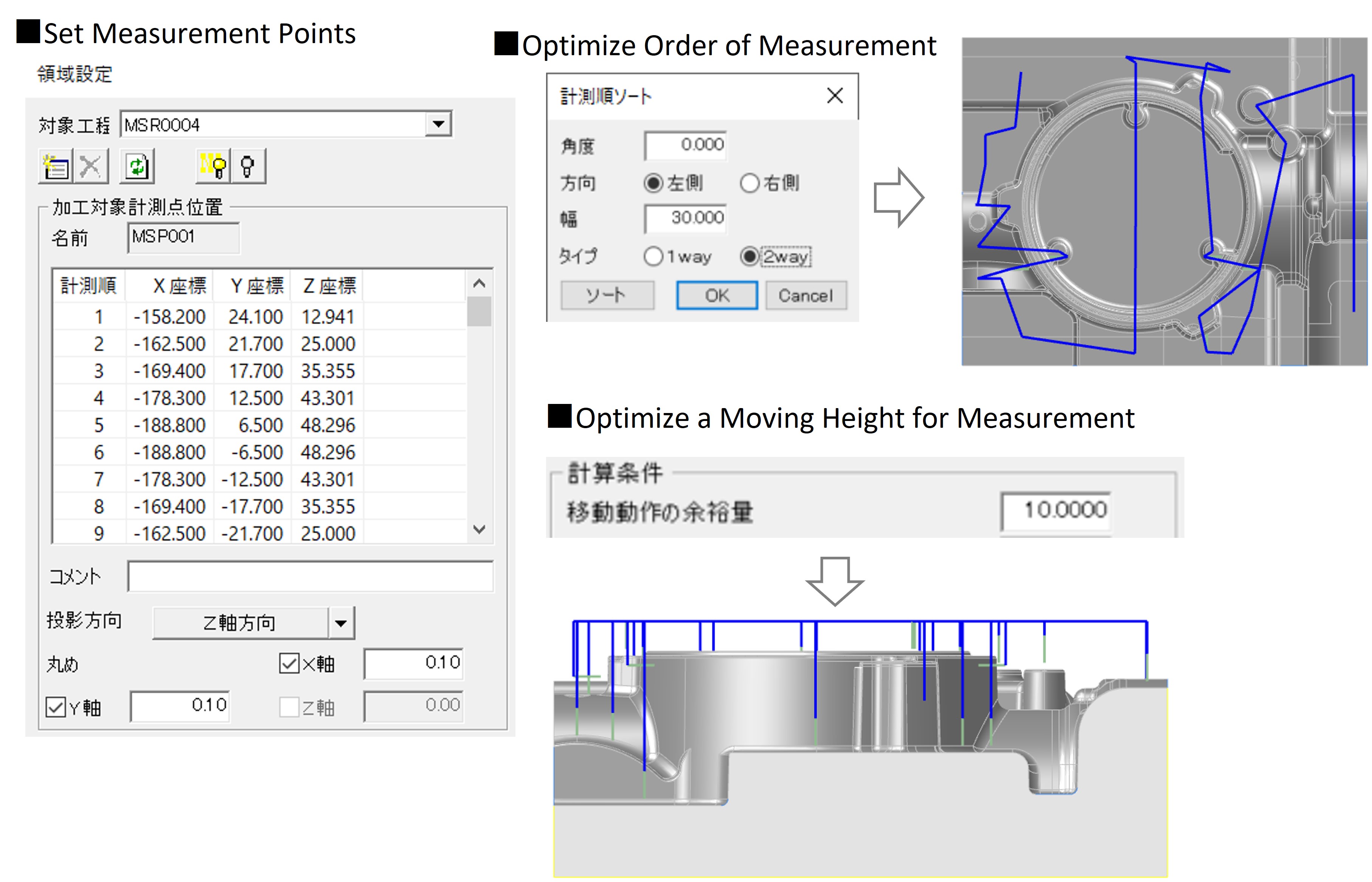

This module CAM-MEASURE specifies any arbitray point or CAD Element Point as a measurement point, and automatically projects it on product surfaces.

This module automatically rounds decimals of a number that indicates a measurement position to the nearest whole number if an axis is specified as a projection direction.

This module reduces a measurement duration to a minimum by re-arranging an order for a gauge head to move from a measurement point to another and also optimizing a height for the gauge head to move at among measurement points.

This solution prepares CSV format files composed of coordinate value of measurement point, center coordinate of gauge heads, vectors of direction perpendicular to a surface, and measurement directions. Import measurement results in order to verify machining errors in a machining process.

If you have any inquiries about our product or would like to request a visit to your place for explanation or demonstration, please use the inquiry form.

![]() Inquiry form

Inquiry form